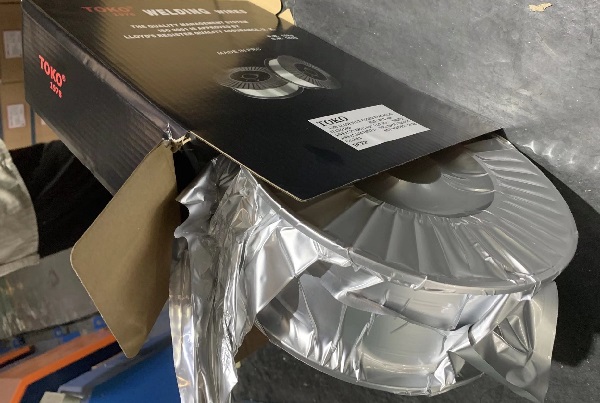

TOKO E71T-1C & E71T-5C Flux-Cored Welding Wire

TOKO E71T-1C and E71T-5C CO₂ gas shielded flux-cored welding wires deliver consistently reliable welding performance for mild steel applications. Proven customer satisfaction across shipbuilding, structural fabrication, offshore construction, heavy machinery, and general industrial applications. Excellent for all-position welding with high deposition rates and minimal spatter.

Key Advantages

- AWS A5.20 Compliance: Meets rigorous industry standards for flux-cored electrodes in structural and industrial applications.

- CO₂ Gas Shielded: Optimized for use with 100% CO₂ shielding gas (20–25 L/min flow rate) providing excellent arc stability.

- All-Position Welding Capability: Superior performance in flat, horizontal, vertical, and overhead positions for versatile applications.

- High Deposition Rates: Efficient for fast-paced fabrication, construction, and repair work with minimal downtime.

- Available Diameters: 0.8mm to 1.6mm spools suitable for various material thicknesses and applications.

Performance Benefits for Industrial Applications

- Excellent Arc Stability: Smooth, consistent arc performance with minimal spatter for cleaner welds and reduced cleanup time.

- Superior Weld Quality: Produces high-quality welds with excellent bead appearance and mechanical properties.

- Easy Slag Removal: Slag detaches easily after welding, increasing productivity in high-volume applications.

- Versatile Applications: Suitable for a wide range of mild steel thicknesses and joint configurations.

Primary Industrial Applications

TOKO E71T-1C and E71T-5C are specifically designed for demanding applications requiring reliable, high-quality welds in structural and industrial settings.

Offshore & Marine Construction

Drilling rigs, production platforms, offshore wind turbine foundations, marine structures, and docks. Excellent for welding in various positions under challenging conditions.

Shipbuilding & Marine Repairs

Hull construction, decks, bulkheads, superstructures, and marine equipment fabrication. Reliable performance for shipyards and marine repair facilities.

Structural Steel Fabrication

Building frames, bridges, industrial structures, commercial buildings, and infrastructure projects. Ideal for welding beams, columns, and structural connections.

Heavy Equipment & Industrial

Construction machinery, mining equipment, agricultural machinery, material handling systems, and industrial plant maintenance and repairs.

Additional Application Areas

- Construction and infrastructure projects including bridges and buildings

- Pipeline fabrication and repair for water, oil, and gas applications

- Storage tank construction and maintenance

- Railway car manufacturing and repair

- Truck and trailer fabrication

- Heavy machinery and equipment manufacturing

- Industrial plant maintenance and repair

- General fabrication and repair shops

Technical Specifications

Chemical Composition (%) - Typical Values

| Element | E71T-1C | E71T-5C | Function |

|---|---|---|---|

| Carbon (C) | ≤0.12 | ≤0.12 | Strength and hardness control |

| Manganese (Mn) | ≤1.75 | ≤1.75 | Strength and deoxidization |

| Silicon (Si) | ≤0.90 | ≤0.90 | Deoxidizer and fluidity |

| Sulfur (S) | ≤0.020 | ≤0.020 | Impurity control |

| Phosphorus (P) | ≤0.020 | ≤0.020 | Impurity control |

Mechanical Properties

| Property | E71T-1C | E71T-5C | Test Standard |

|---|---|---|---|

| Tensile Strength | 490-670 MPa | 490-670 MPa | AWS A5.20 |

| Yield Strength | ≥400 MPa | ≥400 MPa | AWS A5.20 |

| Elongation | ≥22% | ≥22% | AWS A5.20 |

| Impact Energy (-20°C) | ≥27 J | ≥27 J | Charpy V-notch |

Recommended Welding Parameters

| Wire Diameter | Current (A) | Voltage (V) | Wire Feed Speed | Shielding Gas |

|---|---|---|---|---|

| 0.8 mm (0.032") | 120-200 | 18-24 | 4-8 m/min | 100% CO₂ |

| 1.0 mm (0.039") | 150-250 | 20-26 | 4-7 m/min | 100% CO₂ |

| 1.2 mm (0.047") | 180-280 | 22-28 | 4-6 m/min | 100% CO₂ |

| 1.6 mm (0.063") | 220-320 | 24-30 | 3-5 m/min | 100% CO₂ |

E71T-1C vs E71T-5C Comparison

| Feature | E71T-1C | E71T-5C |

|---|---|---|

| Slag System | Rutile-based slag system | Basic slag system |

| Operating Characteristics | Smooth spray transfer, excellent bead appearance | Spray or globular transfer, excellent low-temperature impact toughness |

| Slag Removal | Easy slag removal | Good slag removal |

| Typical Applications | General fabrication, structural welding, shipbuilding | Applications requiring better low-temperature toughness |

Technical Documentation & Certifications

Download comprehensive technical data, material certificates, and safety information for your project specifications and quality assurance requirements.